The shape design of steel fiber overcomes the defects that the deformed parts of general special-shaped steel fibers (such as corrugated steel, arch steel, etc.) are easy to straighten, and have good reinforcement and toughening effect; in order to ensure that the failure of fiber reinforced concrete structure is ductile failure rather than brittle failure, it is necessary to design the deformation parts of steel fiber reinforced concrete structure to ensure that the fibers at both ends of the cracks in the anchored concrete are anchored The tensile strength of steel fiber itself must be greater than its breaking stress

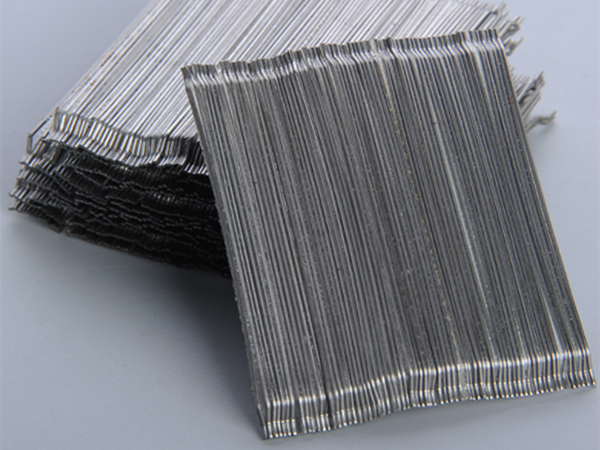

The short fibers randomly distributed in steel fiber reinforced concrete are mainly used to slow down the expansion of micro cracks and the occurrence and development of macro cracks in concrete. In order to make the steel fiber more evenly dispersed in mortar or concrete and increase the length diameter ratio of fiber, steel fiber with water-soluble adhesive can be used to form bundles. Steel fiber can be made by cutting cold drawn steel wire, cutting thin steel plate, milling steel block or ingot, and drawing yarn of molten steel. Low carbon steel fiber can be used to prepare steel fiber reinforced concrete applied at room temperature, while stainless steel fiber must be used to prepare fire-resistant steel fiber concrete. Adding proper amount of steel fiber into mortar or concrete can improve its tensile strength, bending strength, toughness and impact strength. In the initial stage of stress and bending, the fiber and cement matrix bear the external force together. Therefore, steel fiber reinforced concrete has a series of superior physical and mechanical properties.

Compared with ordinary concrete, the impermeability of steel fiber reinforced concrete has no obvious change. Fiber reinforced concrete has the advantages of good crack resistance and integrity. Therefore, steel fiber reinforced concrete has the advantages of high freeze-thaw resistance, heat resistance, wear resistance, cavitation corrosion resistance and corrosion resistance. After 150 freeze-thaw cycles, the compressive strength and flexural strength of concrete with 1.5% fiber decreased by about 20%, while the compressive strength and flexural strength of ordinary concrete decreased by more than 60% under the same conditions. After 200 freeze-thaw cycles, the steel fiber reinforced concrete specimens are still in good condition.