Industrial floor generally refers to industrial concrete floor, compared with commercial floor, industrial floor pays more attention to: wear resistance, compression resistance, high bearing capacity, etc.

1. Emery hardened floor (can be used in heavy machinery plant, hardware factory, glass factory, etc.) is also known as emery wear-resistant floor. The main auxiliary material is emery material. The addition of emery material can increase the particles of floor, change the rigidity of cement and improve the bearing capacity of floor. It can withstand the rolling of heavy objects, such as forklift, forklift, transportation and loading. In the industrial floor, the emery hardened floor is very good in cost performance.

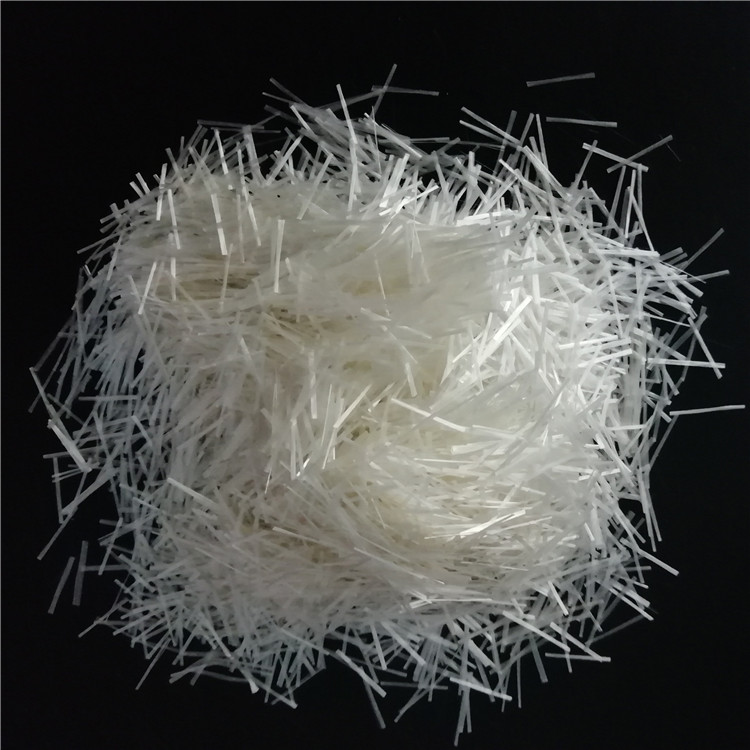

2. Epoxy resin glass fiber anti-corrosion floor (can be used in electroplating plant, circuit board factory and environment ground with acid and alkali corrosion). Generally speaking, the floor with chemical materials stacked for a long time in laboratory and chemical plant needs the anti-corrosion floor property very much. The general floor is not resistant to acid and alkali, and is easy to be corroded by chemical products. And epoxy resin glass fiber anti-corrosion floor can effectively solve this problem.

3. Epoxy resin floor (can be used for floor decoration of electronic factory, food factory, clothing factory, etc., dust-proof, moisture-proof, anti-static). Epoxy floor is not epoxy paint floor. There is a big difference between them. Epoxy floor is a kind of floor paint (water-soluble paint), which is not resistant to temperature changes, and its surface is only a thin layer of paint. It is not suitable for industrial floor, the general heavy rolling will cause blistering, cracking, breaking skin and so on. The epoxy mortar floor is a good solution to this problem. The paving of epoxy mortar can increase the toughness and density of the floor. At the same time, it can effectively improve the bearing capacity.

4. Epoxy terrazzo floor is a new type of terrazzo material. Compared with the traditional terrazzo material, it has better hardness and toughness, and is not easy to crack. It is suitable for commercial floor and industrial floor. It can also be combined with the industrial construction of art floor.

5. Concrete curing agent floor (can be used in large factories, logistics warehouses, production workshops, supermarkets, hospitals and other places. Dust proof, purification, good environment, no dust, no sand) need to go through two times of grinding, respectively, primary grinding and fine grinding, and then sealing and solidification. This effect is better, and the larger the construction area, the higher the hardness, which can form a grid like hardness.