1、 Introduction:

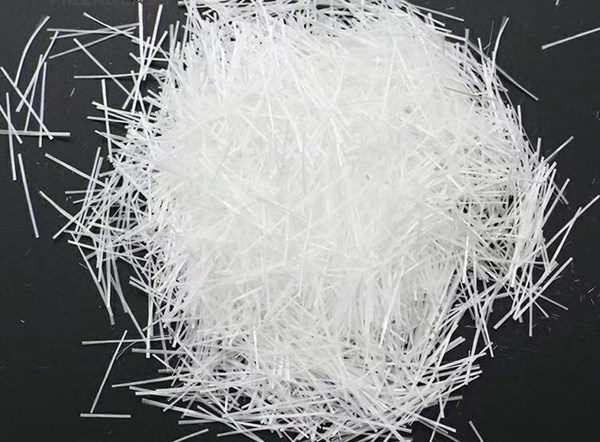

Reinforced fiber is a kind of alkali resistant glass fiber (AR glass fiber) processed by unique production technology. It can effectively control the micro cracks caused by plastic shrinkage, drying shrinkage, temperature, humidity and other factors of concrete or cement mortar, prevent the generation of cracks and effectively inhibit the expansion of cracks, and greatly improve and improve the comprehensive ability of concrete to resist penetration, impact load, chemical erosion, high-speed water flow and bed load abrasion, Prolong the service life and long-term durability of the structure.

Due to AR-glass fiber excellent quality, excellent chemical stability and good affinity with concrete material interface, good dispersion in concrete, simple construction process and convenient operation, it can improve the workability of new retaining concrete, and has remarkable comprehensive economic benefits It has been widely used in dozens of projects in municipal and other fields.

2、 Function:

1. Inhibit the occurrence of cracks or cracks and prevent the further development of primary defects or microcracks in the matrix;

2. Form micro fiber cement crystal interleaving structure to improve the mechanical properties of the matrix;

3. Improve the deformation resistance of the matrix, improve the ductility and toughness of the concrete, and improve the impact and abrasion resistance;

4. Improve the temperature deformation performance of concrete and prevent early thermal cracks of concrete.

3、 Instructions and methods of use:

AR-glass fiber will not produce any chemical reaction with various components in concrete (cement, fly ash, silica fume, bone powder, water reducing agent, water diversion agent, etc.), and there are no special requirements for mixing, vibrating and conveying equipment. During construction, the disassembled fiber can be directly added to the mixing equipment according to the concrete mix proportion.

4、 Main technical parameters and performance:

1. The volume content is 0.05% - 0.20% of the concrete volume;

2. The fiber type is bundle monofilament;

3. The breaking tensile rate is 3% - 4%;

4. Specification: 6mm, 12mm;

5. Tensile strength 1500-6000mpa;

6, good aging resistance.

7. Nominal diameter about 7-11 μ m.

5、 Precautions:

1. In case of low content, the original concrete mix proportion does not need to be changed;

2. The addition of fiber can enhance the cohesion of concrete and slightly reduce the slump, but it will not affect the workability of concrete. On the contrary, it can reduce the bleeding of concrete and aggregate segregation. Never increase the water consumption and change the water cement ratio of concrete because of the decrease of slump. If the slump is to remain unchanged, the dosage of water reducing agent can be adjusted;

3. The implementation of codes and maintenance measures shall not be relaxed due to the use of fibers in concrete.

4. After contact with fiber, individuals may have slight skin allergy or discomfort. Don't worry, please rinse with clean water;

5. It is recommended to wear protective glasses during fiber concrete construction to avoid eye irritation.

6、 Application fields:

1. Parts and occasions requiring crack resistance of concrete surface, such as: strong plastering mortar inside and outside buildings, dam overflow surface concrete, crack resistance concrete in strong constraint area of dam foundation, prefabricated concrete components of pipe piles, prefabricated concrete tiles of tunnels, highway pavement, bridge deck concrete, airport runway, apron, municipal road and bridge works, etc;

2. Concrete parts with frequent temperature difference changes and large temperature gradient, which are prone to temperature difference cracks;

3. As non structural or temperature difference compensation reinforcing material;

4. Concrete engineering parts resistant to acid-base and other chemical corrosion;

5. Concrete with high requirements for impact resistance, abrasion resistance and earthquake resistance, such as dam discharge hole, beam column of high-rise building, railway sleeper, plant structure, tailrace cone pipe, reinforced concrete volute and secondary foundation concrete around steel volute, concrete around dam Gallery, Backfill Concrete of mechanism equipment base, etc;

6. Excavation slope reinforcement and shotcrete support, cavern top arch, side wall shotcrete support, foundation grouting, etc,

7. Parts requiring concrete impermeability, such as impervious layer concrete on the upstream surface of gate and dam, cushion concrete on the contact surface of new and old concrete, rigid waterproof concrete or mortar on the roof, side wall and floor of basement.